METAL PRODUCTS FOR FOOD PRODUCTION

High-quality design, engineering development and modern programming for equipment in the food industry is extremely important, because the taste of the final consumer product depends on these three stages.

Our company has experience in ensuring fast and correct organization of food equipment - from receiving raw materials to product packaging.

Today the market is very dynamic, rapidly evolving and needs constant improvement. The main requirements for food equipment are: high manufacturability, efficiency, reliability and ease of use.

Our designers, technologists and engineers follow global trends and innovations to keep up with the times and needs of the food industry, including confectionery bakeries, to offer you the best solutions.

If your activity is related to baking bakery and confectionery products. Your business belongs to the bakery industry: bakeries, bakeries, bakeries, confectioneries - then we can build a reliable partnership. We participate in the improvement, service and design, development and launch of new equipment for your needs.

Services

DOUGH MIXER

Dough mixer is one of the most important elements of baking and confectionery production.

With this machine you can get a uniform, homogeneous mass of the desired consistency, without lumps and undissolved ingredients, which is the main factor for a delicious finished product.

The design of the kneading machine provides for the presence of three components: the kneading element, the tank for kneading and the drive. The first can be presented in the form of a spiral, a shovel, one or two loops, a fork. It saturates the dough with oxygen, which makes the product lush.

The operation of the drive is based on one of three principles: belt, gear or chain. This mechanism starts the whole system.

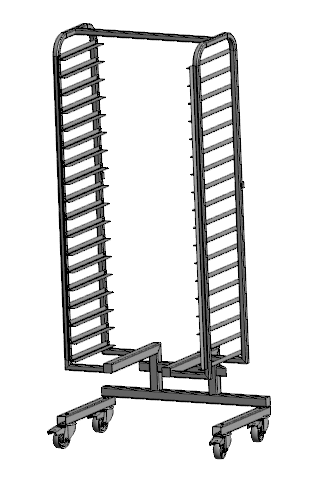

DOUGH STAND CAMERA

Dough stability chambers are designed for stability of baking for bakery and confectionery producers.

Dough stability is a modern technological process that can be created because the yeast actively processes the sugar available to it, creating carbon dioxide, which collects in bubbles and is therefore suitable. An important factor for this process is a certain stable temperature and humidity.

The rack chambers which we make allow to maintain necessary temperature in necessary technological frameworks by means of the established automatic equipment.

Our specialists have a good understanding of the specifics of this equipment and take into account all the important factors to obtain a quality end product. Modern technology and automation allows you to design reliable and comprehensive solutions for uniform circulation of hot air, the required humidity and adhere to one level of the desired temperature.

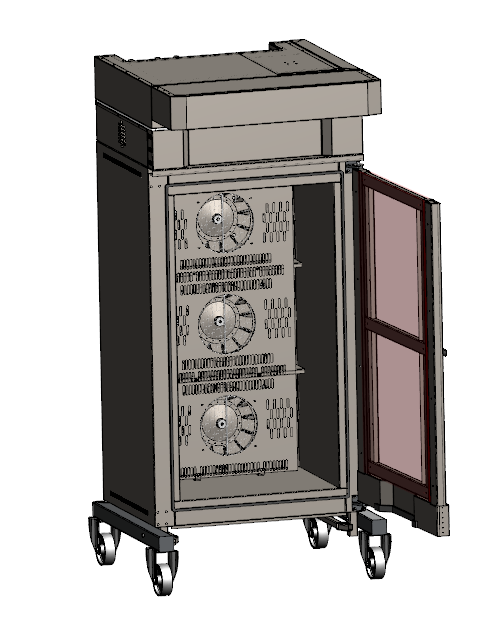

PARACONVECTOR

The convector plays an important role in the hot shop from the catering establishment to the bakery production.

This device works in three versions:

- convection technology (hot air circulation)

- use of a steam generator (ensuring the presence of steam in the chamber)

- combined method of cooking (combination of the previous two).

The main element of convectors is an oven, or as it is called, a working chamber. It is usually made in a seamless version, without corners and is easily hygienic. It is important to note that such an oven is always airtight when the door is completely closed.

The presence of steam in the oven prevents the products from drying out, and the presence of hot air guarantees even roasting.

The main advantage of using a convector in a hot shop or confectionery bakery is the reduction of cooking time.

GLAZING MACHINE

We design, develop and install a machine that covers cakes, candies, cakes, cupcakes with confectionery semi-finished products.

Having established a decorator to glazing it is possible to put various patterns on a product.