Industrial automation

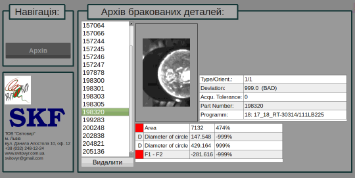

We are working in Industry 4.0, which vision is that in the future, industrial enterprises will build global networks to connect their machines, factories and warehouses as cyber-physical systems that will intelligently connect and control otherwise through the exchange of information that triggers action.

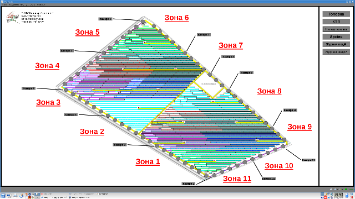

Industry 4.0 supports decentralization, which allows different smart factory systems to make decisions autonomously, without deviating from the path to a single, ultimate organizational goal.

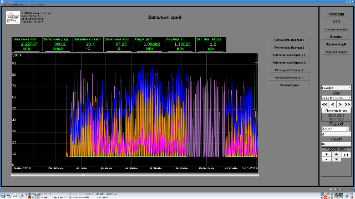

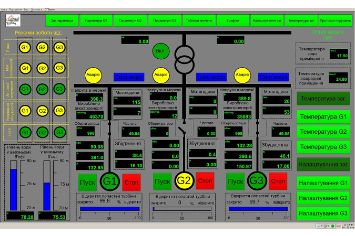

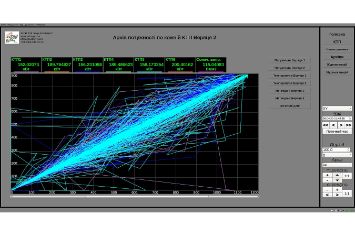

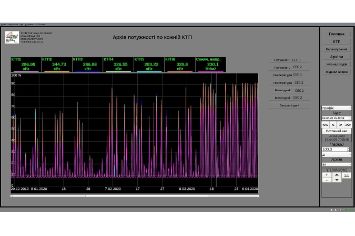

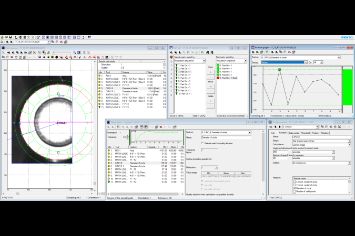

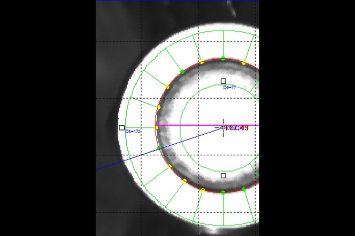

The efforts we make are as focused as possible on doing everything in real time, everything is needed to ensure that the production process collects data, and that feedback and process monitoring is also achieved in real time.

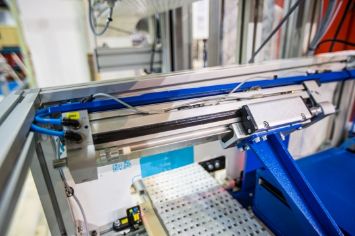

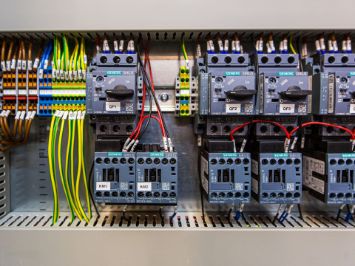

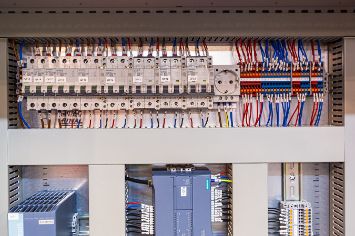

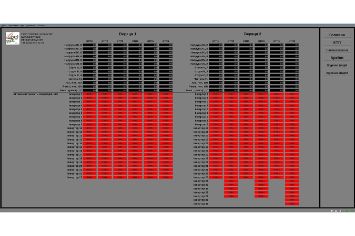

A wide range of services for automation of production processes includes: programming of industrial PLC controllers, HMI machine control panels, development of SCADA systems for plant management. Pneumatics, mechanics, hydraulics, electricity, mechatronics. We develop schemes, model, prototype, sample, industrial solution, we approach each Client individually.